Finding and Training Up Skilled Workers with AI: How Car Repair 4.0 is Laying the Groundwork

Juan Hahn from the Car Repair Shop 4.0 consortium assesses the short supply of skilled workers in the car repair sector and the positive impact of AI support.

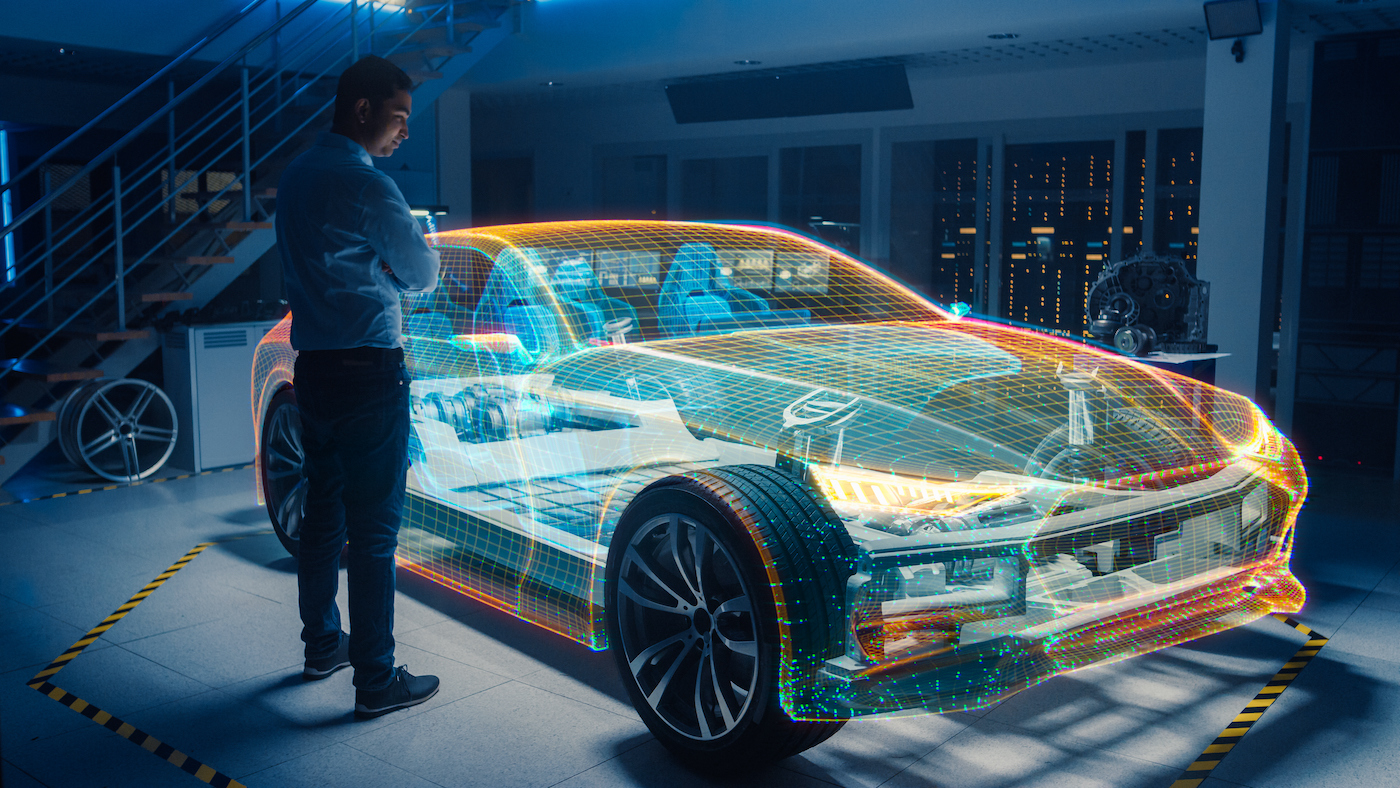

© pakorn sungkapukdee | istockphoto.com

Ralf Schädel: Juan, in your opinion, what is the reason for the fact that the number of apprentices in the automotive sector is stable throughout Germany, but there is still a problem with young talent?

Juan I. Hahn: Over the course of the last few years, we have seen that the number of employees and trainees has been stable. However, the number of vehicles has increased constantly. According to the German Federal Motor Transport Authority, there were over 48.54 million vehicles in the first quarter of 2022. This is the highest figure ever.

Broken down to the individual car repair shops, this means that there are more orders than one store can handle. If we take into account that the number of repair shops is declining, companies’ need for apprentices has increased – as has the burden on individuals. Because there are fewer applicants per apprenticeship position, the problem of new recruits presents itself as a loss of quality.

Schädel: We hear from repair shops that more and more entry-level employees are not interested in oil-smeared hands and physically very strenuous work. What are the reasons?

Hahn: The mechatronics profession needs to be more attractive and equipped with more digital media. For young people, there is no digital transformation. Their world is digital from the start. So why would a young person be interested in a non-digital workplace?

They are used to using a smartphone, and their cognitive skills are trained on digital content. As a result, they can retrieve knowledge much faster than generations before. Diagnosing and repairing a vehicle would have to be much more digital.

Schädel: What is the connection between the change in the job description of “mechatronics technician” and that of the entire automotive industry?

Hahn: Digitalization is a challenge for the entire industry in general. Specifically related to the profession of mechatronics engineer, the profession of mechatronics engineer must become more attractive and - as I said - more digital...

Schädel: ... do you have an example?

Hahn: On a meta level, in addition to digitalization, the major challenges facing the industry are electromobility, sustainability, and securing skilled workers. The best example is diagnostics. It is very complex, lengthy, and often does not lead to a concrete result with conventional measurement methods. Unsuccessful repair attempts frustrate repair shop employees and customers alike.

Schädel: Will the upcoming generational change in repair shop master tradespeople exacerbate the shortage of skilled workers?

Hahn: I don’t necessarily see the generation change as the reason. Rather, the aforementioned increase in motor vehicles coupled with the complexity of the technologies and the associated difficulty in troubleshooting in a targeted and efficient manner is leading to an exacerbation.

Schädel: Can Car Repair 4.0 give independent repair shops a more attractive image?

Hahn: Yes, definitely. A project like Car Repair 4.0 has a significant impact on image. Especially because it improves the customer experience. Employees can identify with the fact that a defect is found and fixed. Collaboration with AI is also exciting and “fancy”.

Schädel: What else can AI-supported automotive fault diagnosis in an ecosystem do to make independent workshops and their staff fit for the future?

Hahn: The ability to perform more specific troubleshooting on a vehicle, i.e., to diagnose more efficiently, is crucial to dealing with the complexity of vehicles. The formation of an ecosystem like that of Gaia-X can securely connect different data streams within the workshop...

Schädel: ... networking the data of many car repair shops as well.

Hahn: We want to show strands of action. It is important for a repair shop to be able to benefit from the knowledge of others. Information sharing is the basis for knowledge. The access method and framework to the data provide the basis for working securely and trustfully.

Schädel: More competitiveness compared to contract repair shops will add “sexy” to the equation. Is AI a game-changer?

Hahn: In the end, we will form AI models that work for independent repair shops as well as for the contract repair shops. As a member of the Gaia-X family, we have European sovereignty in mind.

This is important for all companies in Europe. No matter from which industry or branch. We expect everyone to think outside the box and act together in a strategically sustainable way.

We offer a fair playing field and a technologically suitable ecosystem for this. Whether our AI becomes a game-changer depends on the quantity and quality of the data we receive and collect in order to for the AI to learn. And that, in turn, depends on the willingness of market participants to actively participate in Car Repair 4.0. Fortunately, the market seems to have understood this. Accordingly, the response has been very positive and extensive.

Schädel: Car Repair 4.0 wants to demonstrate the feasibility of AI. Does the project also indirectly influence recruiting?

Hahn: We want to provide potential from which the private sector may develop digital business models. In terms of AI model development, more accurate diagnostics should be possible with an oscilloscope. In terms of research and the in-depth research we are doing in the project in the area of “aftersales” and in terms of feedback from different stakeholders, we are, of course, also questioning the status quo in recruiting.

If, in the future, carrying out a diagnosis no longer leads to the job profile of a service advisor but possibly to a new role – for example, that of a pure “vehicle inspector” – then the project will definitely have an impact on recruiting. Such a role could possibly place fewer demands on the applicant.

Schädel: In which other repair shop areas does the project want to use AI to leave a footprint in the future?

Hahn: Companies that are opening up to technologies such as artificial intelligence in the course of digitalization are fundamentally interested in rethinking processes and services. We simply provide the impetus for change and want to show what is possible when you focus on a topic, methodically and systematically collect data, evaluate it and ultimately develop AI models. This is something that other fields of work and research as a whole are welcome to follow.

My role in the project is precisely to ensure that the development does not become too abstract and that we gain sufficient depth across all stakeholders in the automotive industry. Perhaps that also sets us apart somewhat from other projects. I am glad to have Dr. Jan Schoenke from the consortium leader, LMIS AG, as a partner – he is investing in this necessary structural groundwork. For us, the “pains” and “gains” of the market are in the foreground and only afterwards comes the technological consideration of the “feasible”. In this way, we ensure that we do not ignore the market.

Juan Hahn is the owner of the HAHN Network, which supports companies in the digitalisation of mobility services and car trade with business development advice.

Ralf Schädel is IT Editor and Project Manager Cloud Services and Gaia-X at eco – Association of the Internet Industry.

Please note: The opinions expressed in Industry Insights published by dotmagazine are the author’s own and do not reflect the view of the publisher, eco – Association of the Internet Industry.